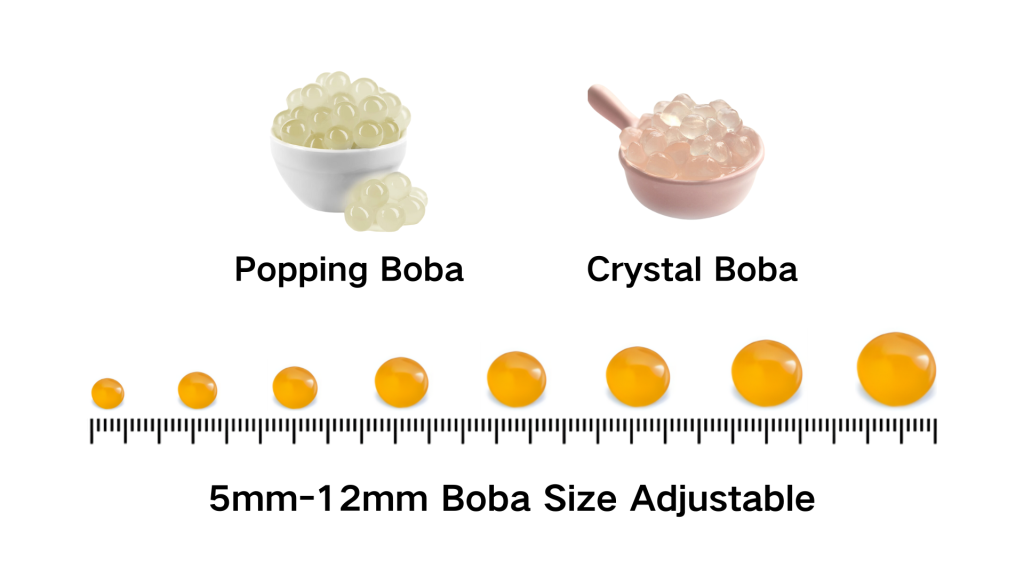

The two types of products the machine can produce:

Specifications

| Model | Capacity | Electric power needed | Number of nozzles | Dimension | Boba Size |

|---|---|---|---|---|---|

| CBZ50A | 50kg/h | 61kw (Electric heating) 30kw (Steam heating) |

30 pcs | 6500mm*3500mm*1800mm | 5-12mm |

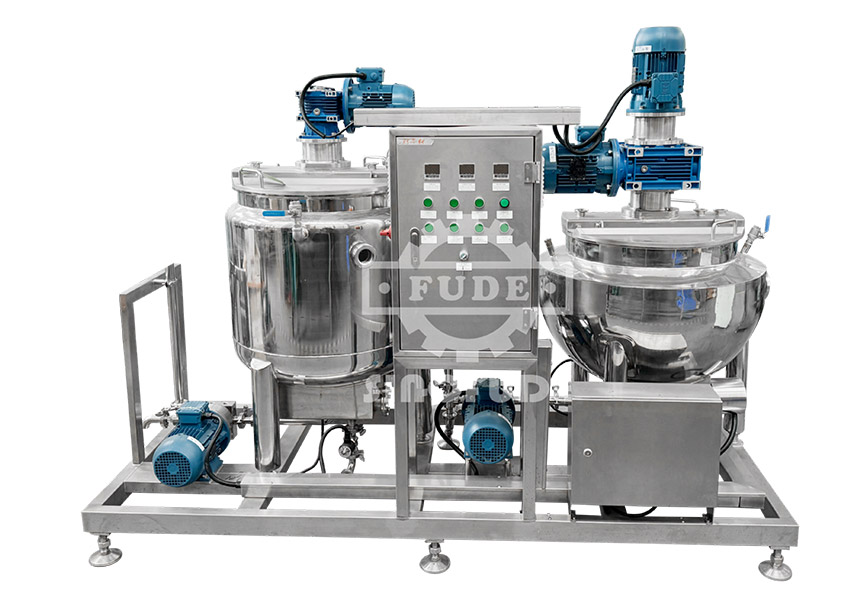

Cooking system

The raw material processing part of the CBZ50A production line. Sodium alginate solution, syrup, etc. are cooked here. It consists of 2 cookers, 2 storage tanks and transfer pumps. It can be equipped with a high-speed shearing machine and 3-layers insulation jacket cooking.

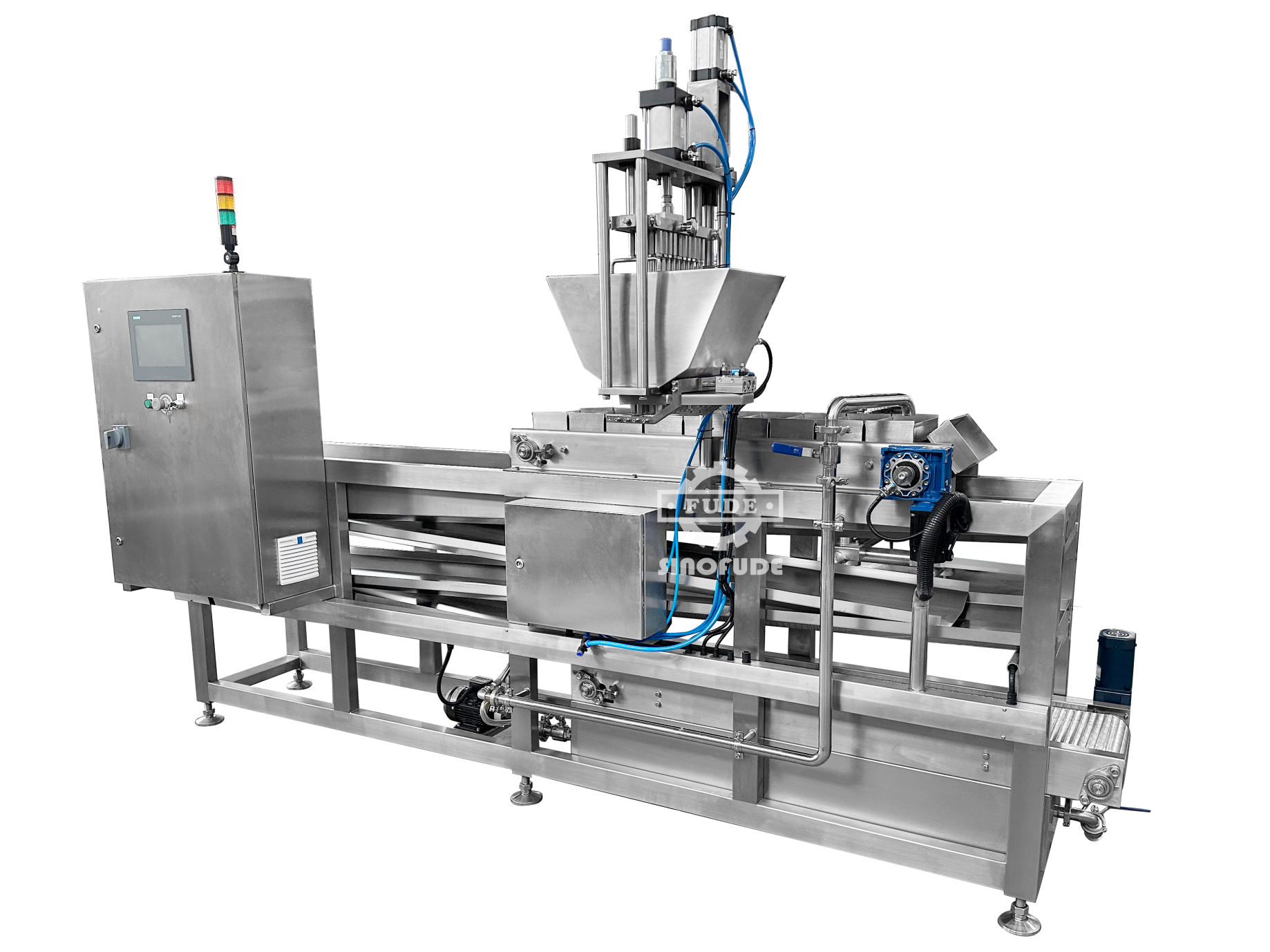

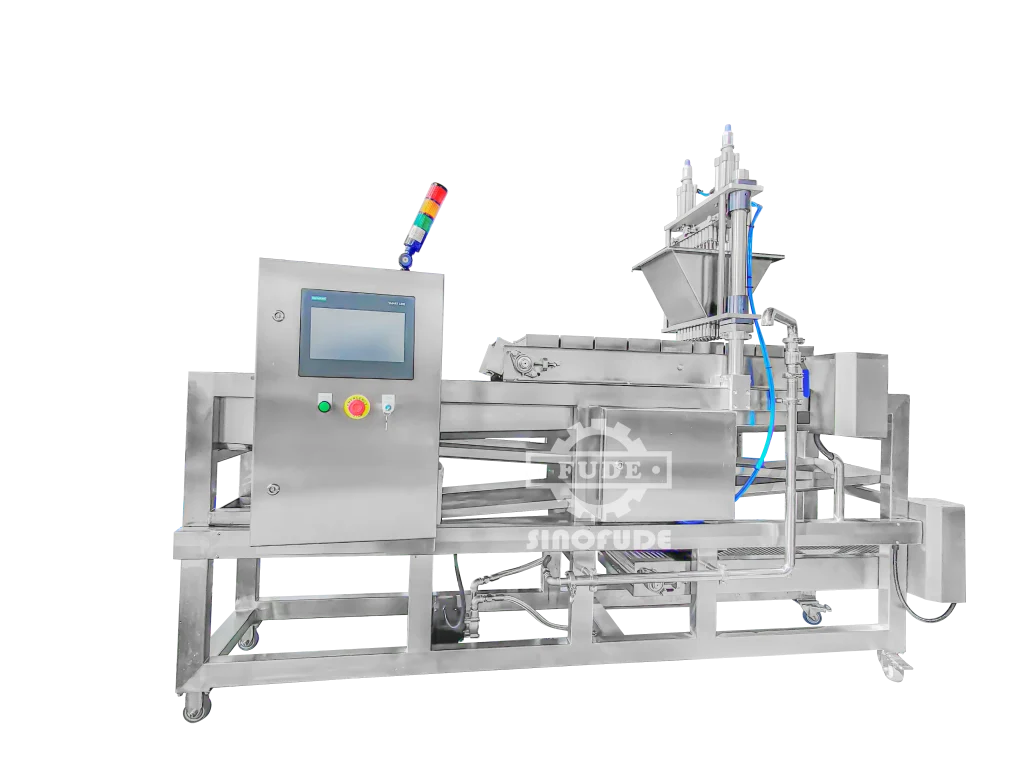

Depositing system

The equipment was exclusively developed and produced by Shanghai Fude Machinery and was put into production in March 2022. This equipment takes into account the advantages of full automation and small footprint, and is suitable for customers with small capacity requirements but high requirements for full automation.

Scrape and stir

PTFE hanging side mixing to ensure food safety. Round tube design, no welds, no sanitary dead corners. Center high-speed shearing, 100% cutting of macromolecular substances.

Nozzles

0 error nozzle, precise depositing. Replaceable nozzles to support different sizes. Wire cutting is optional and can produce Crystal boba, Konjac boba.

Hopper

No welds inside the hopper and no sanitary dead corners. Optional thermal insulation sandwich hopper. Optional liquid level meter to automatically monitor raw material liquid level.