CBZ200

Home » Popping Boba & Konjac Ball Production Line » CBZ200

SINOFUDE’s CBZ200 full automatic popping boba production line series are especially designed for big capacity popping boba manufacturing. Its capacity can achieve 200kgs/h. And there are two models: CBZ200 and CBZ200S, the former is controlled by cylinder, the later is controlled by servo-motor. What’s more, by changing some small advice, like jacket hopper and cutting wires, this machine can make 3 products: popping boba, crystal boba (konjac boba) and imitation caviar. And the size of the boba can also be adjusted by changing the nozzles or nozzle template.

The three types of products the machine can produce:

Specifications

| Model | Capacity | Electric power needed | Number of depositing nozzles | Dimension | Boba Size |

|---|---|---|---|---|---|

| CBZ200 | 200 kg/h | 75kw (Electric heating) 40kw (Steam heating) |

198 pcs | 6500mm*3800mm*2200mm | 8-12mm |

| CBZ200S | 200 kg/h | 75kw (Electric heating) 40kw (Steam heating) |

4 model templates (no nozzles) |

6500mm*3800mm*2200mm | 3-12mm |

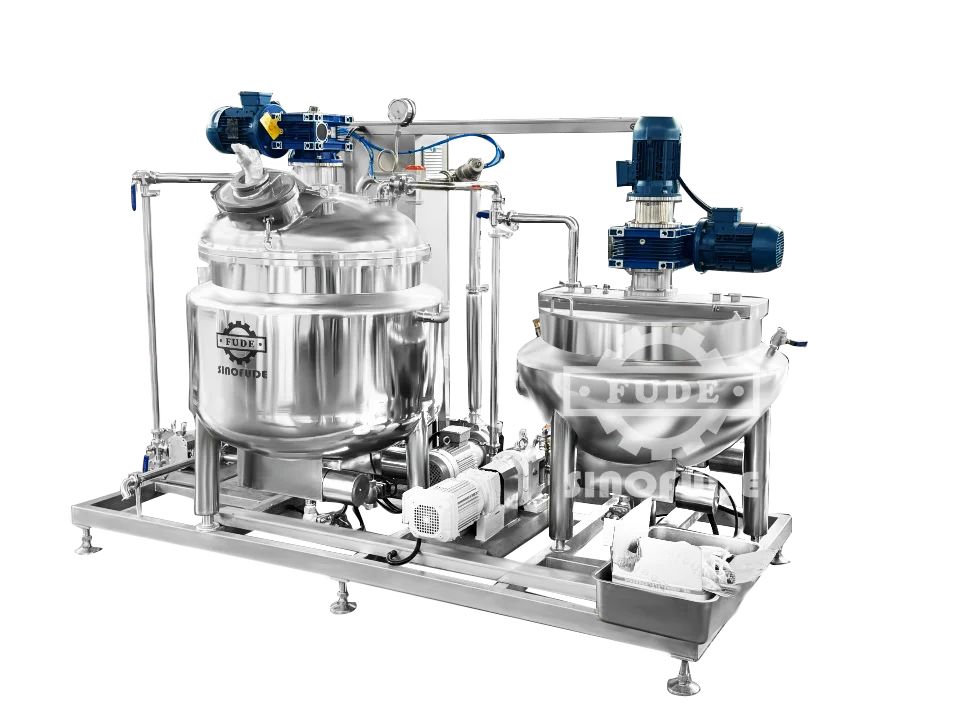

Cooking system

The raw material processing part of the CBZ200 and CBZ200S production line. Sodium alginate solution, syrup, etc. are cooked here. It consists of 2 cookers, 2 storage tanks and transfer pumps and pipes. It also can be equipped with a high-speed shearing machine and 3-layers insulation jacket cooking.

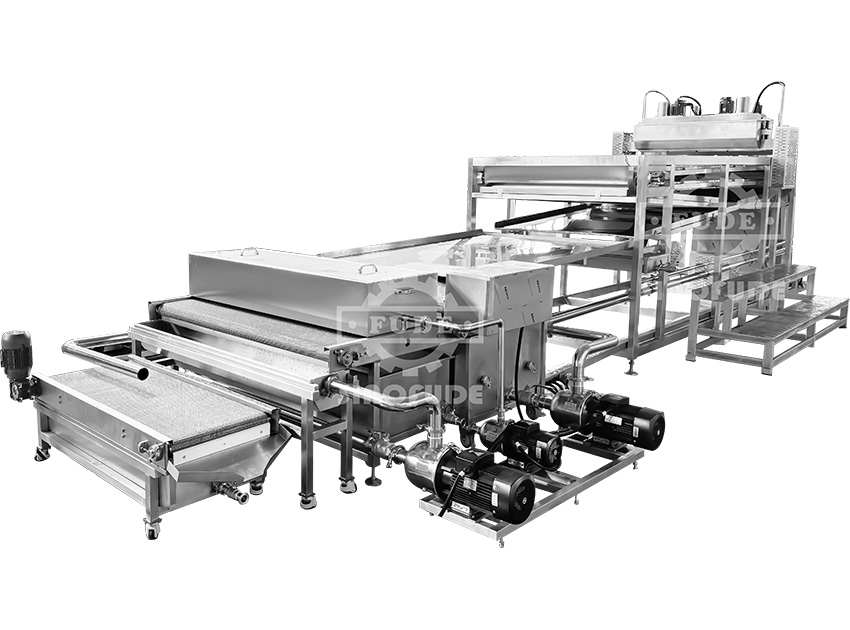

Depositing system of CBZ200S

The upgraded version of the servo drive model’s capacity is 200kg per hour. The size of boba is more precise and easier to control, and it can produce 3mm size imitation caviar by changing the size of two mold template, which is easy to clean and save the labor time.

Scrape and stir

PTFE hanging side mixing to ensure food safety. Round tube design, no welds, no sanitary dead corners. Center high-speed shearing, 100% cutting of macromolecular substances.

Hopper

Driven by servo motor, the depositing amount is more uniform and precise. No piston inside, easy to clean. New internal structure design, with suction function, smooth depositing without tailing

Comparison of depositing methods between CBZ200 and CBZ200S:

CBZ200

CBZ200S

Integrated depositing plate replaces traditional nozzles for faster removal and installation. The minimum diameter is 3mm, which can produce 3mm simulated caviar. Optional insulating cast plate for production of Crystal boba.