CLM40Q

The three types types of products the machine can produce:

Specifications

| Model | Capacity | Boba Weight | Power | Compressed Air | Machine size | Gross weight |

|---|---|---|---|---|---|---|

| CJQ200 | 150-200kg/h | According to ball diameter (Customized from 5~15mm or more) | 5.5kW | 0.5M3/min, 0.4~0.6MPa |

4500X1200X1850 | 1200kg |

| CJQ400 | 300-400kg/h | 7kW | 1.2M3/min, 0.4~0.6MPa |

4500x1200x1850 | 1600kg | |

| CJQ800 | 600-800kg/h | 8.5kW | 1.5M3/min, 0.4~0.6MPa |

5500x1200x1850 | 2500kg | |

| CBZ1200 | 900-1200kg/h | 10kW | 2M3/min, 0.4~0.6MPa |

6500x1200x1850 | 2600kg |

PLC touch screen, every easy to opera

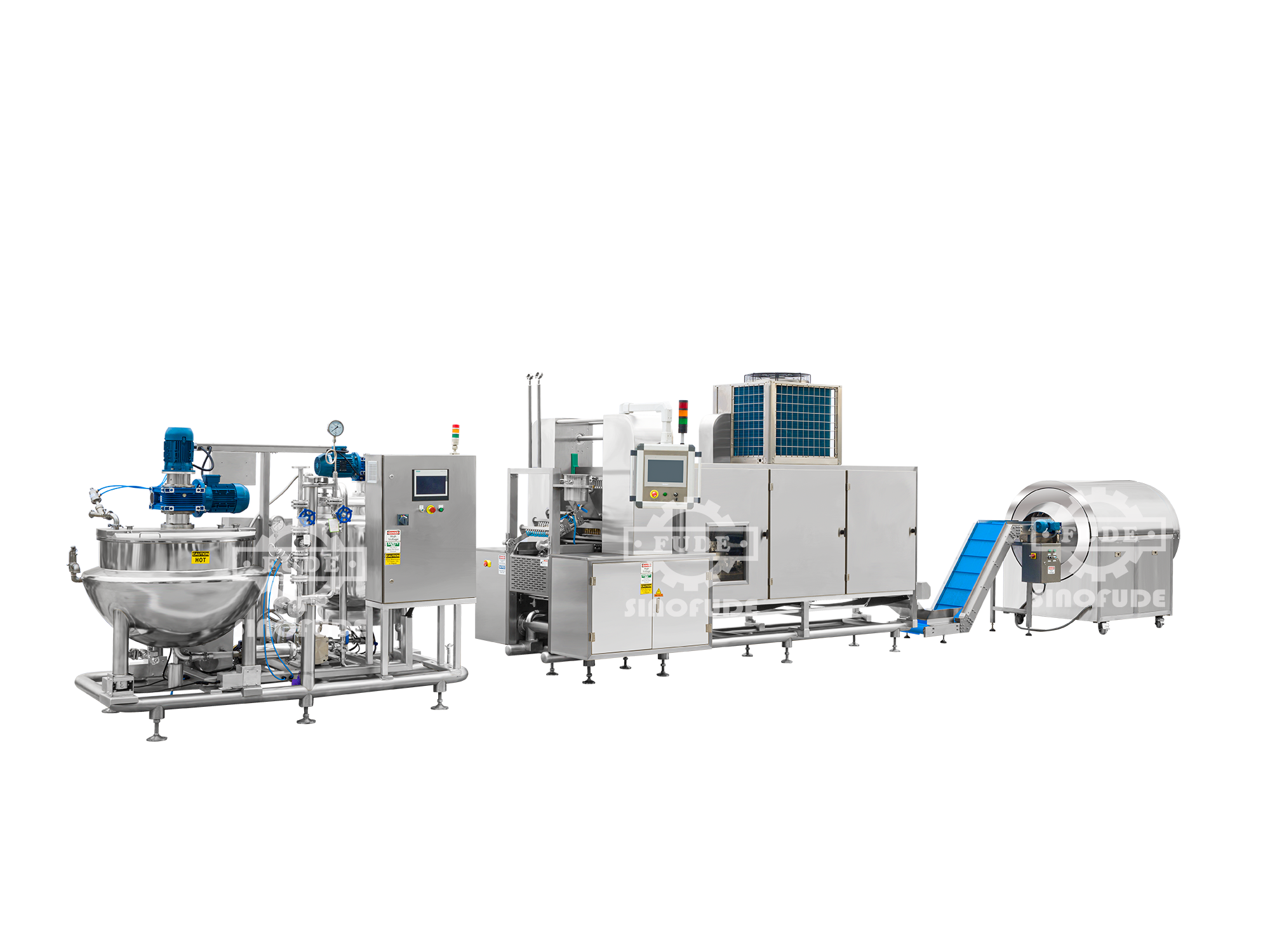

Cooking system

Cooker system-Pectin/Gelatin

1 set of jacketed kettle for melting pectin and sugar, equipped with high shear and variable speed drive.

1 set of pump with variable frequency speed regulation

1 set of hot water circulation system, supply pipes and parts that need to be insulated

1 set of heated storage tank with scraper and variable speed drive for stirring

1 set of cooling tank as an option

1 set of load cells as option

Integrated electrical cabinet and touch screen control of all programs

SS304/316

Color/flavor quantitative system

1-Online mixer for flavor

2-Static mixer for colors, activity material and acids

3-2x20L CFA storage tank and metering pump

Batch CFA system as an optional

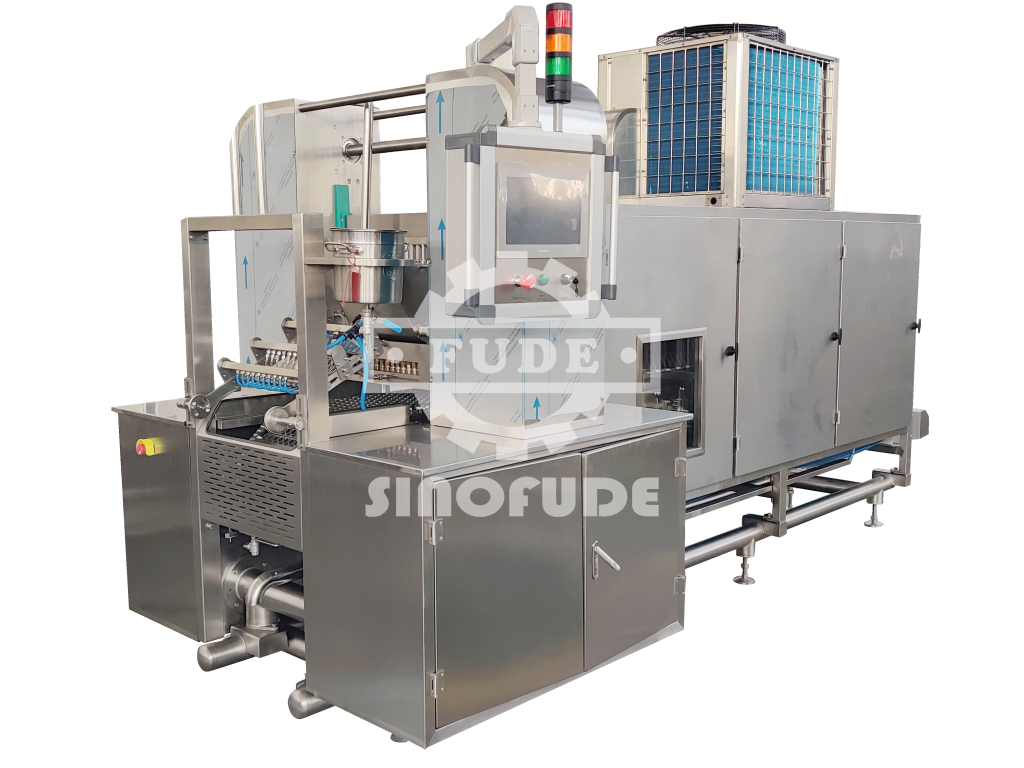

Depositing & Cooling & Demoulding system

-Servo drive system

-Mold quick disassembly

-Teflon coated metal mold or silicone mold with ejector pin

-Quick release chain system

-Hopper heating and insulation system

-Double hopper as option for dual color and center fill candies

-LED HMI 10′ Siemens touch screen

-Double brush blowing and demoulding system

– FDA approved non-stick anti-mold conveyor belt

– 5HP cooling chiller

– Electrical cabinet

Optional items

-Z-shaped lifting conveyor to coating drum

– Available in oils, waxes and sugar