Bag Filling Multi-head Combination Weigher

Home » Bag Filling Multi-head Combination Weigher » Bag Filling Multi-head Combination Weigher

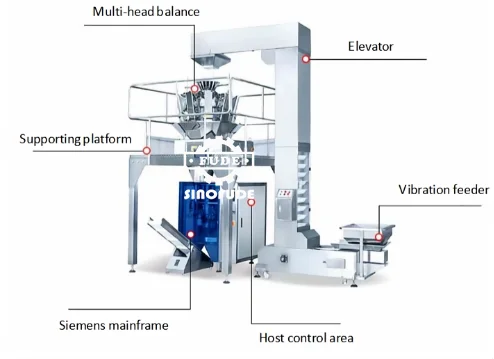

SINOFUDE candy filling multi-head combination weigher is composed of multi-head balance, Elevator, Vibration feeder, Host control area, and Siemens mainframe, Supporting platform. It is suitable for irregular lumpy and granular materials, such as candy, puffed food, small biscuits, fried dried fruit, sugar, frozen food, hardware and plastic products, etc.

The three types types of products the machine can produce:

Specifications

| Model | SF-2.0T | SF-3.0T |

|---|---|---|

| Length range | 100mm-400mm | 100mm-480mm |

| Width range | 80mm-250mm | 80mm-350mm |

| Packing speed(min) | 10-45bags | 20-70bags |

| Package weight | 100-1500 g | |

| Material | 304 stainless steel | |

| Composition | bag feeder + elevator + combination balance + working platform | |

| Metering method | Weighing | |

| Error | ±1% (depending on material) | |

| Applicable material | OPP/CPP, OPP/PE, PET/PE, PE | |

| Power | 220v/380v | |

- The equipment frame is made of 304 stainless steel, which conforms to the food QS and pharmaceutical GMP health standards;

- Equipped with safety protection, in line with the requirements of enterprise safety management;

- Adopt independent temperature control system, temperature control is accurate, ensure the sealing is beautiful and smooth;

- Servo motor film drawing, PLC control, touch screen control, automatic control ability of the whole machine, high reliability and intelligence, high speed, high efficiency;

- Double belt film drawing, film drawing system and color code control system can be automatically adjusted by touch screen, simple operation for sealing and notching correction;

- The touch screen can store a variety of packaging process parameters of different products, and can be used at any time without adjustment when replacing products;

- The machine is equipped with fault display system, which can help troubleshoot in time and reduce the requirement for manual operation;

- The whole set of equipment includes the whole packaging process from material conveying, metering, printing, bag-making, filling, sealing, cutting and product conveying;

- It can be made into pillow bags, gusset bags, hanging bags, and string bags according to customer needs;

- The machine adopts closed structure to prevent dust from entering the machine effectively.

- Safety performance: The machine will automatically stop when the door is opened to prevent injury by the machine.

The product is poured into the bin and transferred to the loading machine bucket through vibration and then transferred to the combination scale for automatic measurement

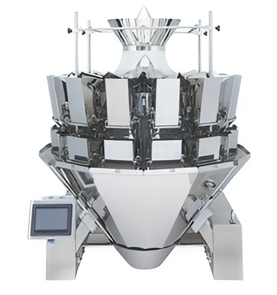

Food grade 304 stainless steel material, high speed and high precision weighing control, modular design, easy to use touch screen operation, multi-language display

The platform is used to isolate the bag machine from the electronic scale so that the vibration generated by the operation of the packaging equipment will not affect the accuracy of the electronic scale, so that the electronic scale can stabilize the speed and accuracy and facilitate the observation and cleaning of the electronic scale

Easy to operate: PLC control, man-machine interface;

Frequency conversion speed regulation: the use of frequency conversion adjustment device can adjust the speed at will within the specified range;

Easy to adjust: controlled by the motor, it only needs to adjust 8 groups of machine clips synchronously by one button;

Oil-free vacuum pump to avoid production environment pollution;

The parts in contact with the material are made of 304 stainless steel, in line with food hygiene standards

Positive pressure blowing bag opening mechanism: Designed for self-supporting bags with thick or sticky bottom material, to avoid affecting the bag volume due to incomplete opening of the bottom