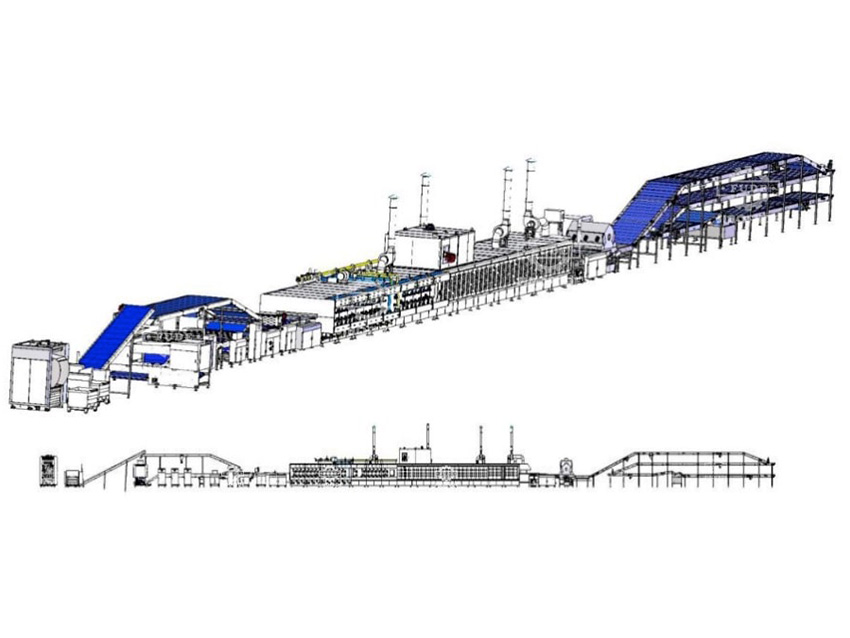

BCM Series

Specifications

| Model | Production capacity(kg/h) | Total length(mm) | Baking temperature(℃) | Whole line power (kw) | Whole line weight (kg) |

|---|---|---|---|---|---|

| BCM-250 | 250 | 29600 | 190-240℃ | 105 | 6000 |

| BCM-480 | 480 | 64500 | 190-240℃ | 190 | 12000 |

| BCM-600 | 600 | 85500 | 190-240℃ | 300 | 20000 |

| BCM-800 | 750 | 92500 | 190-240℃ | 400 | 28000 |

| BCM-1000 | 1000 | 125000 | 190-240℃ | 500 | 35000 |

| BCM-1200 | 1250 | 125000 | 190-240℃ | 600 | 45000 |

| BCM-1500 | 1500 | 150000 | 190-240℃ | 750 | 55000 |

Raw material mixing system

The vertical dough mixer is suitable for producing soda crackers. It mixes the flour at 15rpm or 25rpm.

Equipped with mixing buckets with certain volume, this dough mixing equipment can produce fermented crackers continuously.

Horizontal mixer is designated to make dough.

By kneading, pressing and folding, the mixer makes smooth, elastic and ductile dough which is suitable for hard and soft biscuits.

Forming system

It mainly includes dough conveying, dough recycling, cutting, forming and other units. If equipped with a crisp forming unit and a tough forming unit, crisp and tough biscuits can be produced at the same time.

In addition, it can also be equipped with a crisp forming unit or a tough forming unit separately to produce crisp or tough biscuits.

Moreover, by changing the mold, biscuits of different weights and shapes can be produced.

Bake system

Regarding the baking system, according to customer needs, there are gas furnaces, electric furnaces, and diesel furnaces to choose from.

The oven has the main characteristics of low energy consumption, large capacity, uniform baking, clean and hygienic, precise temperature control, easy operation, convenient maintenance, and wide application range.

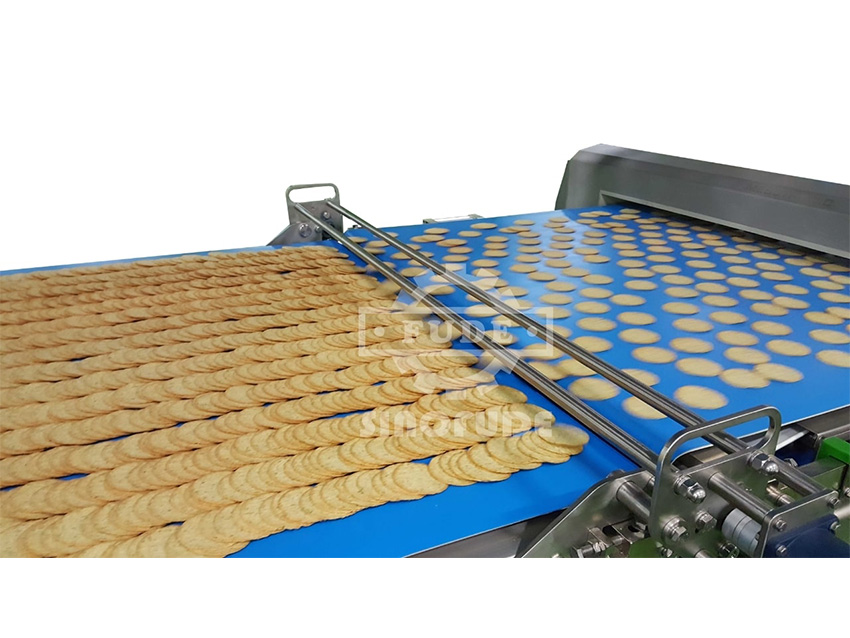

Cool Conveyor system

This conveyor is used for cooling down the biscuits after baking to enable the products complete cool down for arranging and packaging. The design of this cooling conveyor may be varied subject to the different requirements and site environment.

The layout could be straight line, three-layer ”z” shape or suspension type structure The cooling conveyor is used for normal cooling. Made of stainless steel square pipes of proper strength, the cooling conveyor is structurally simple and compact. The whole machine looks light and stable, and is easy to install and remove.

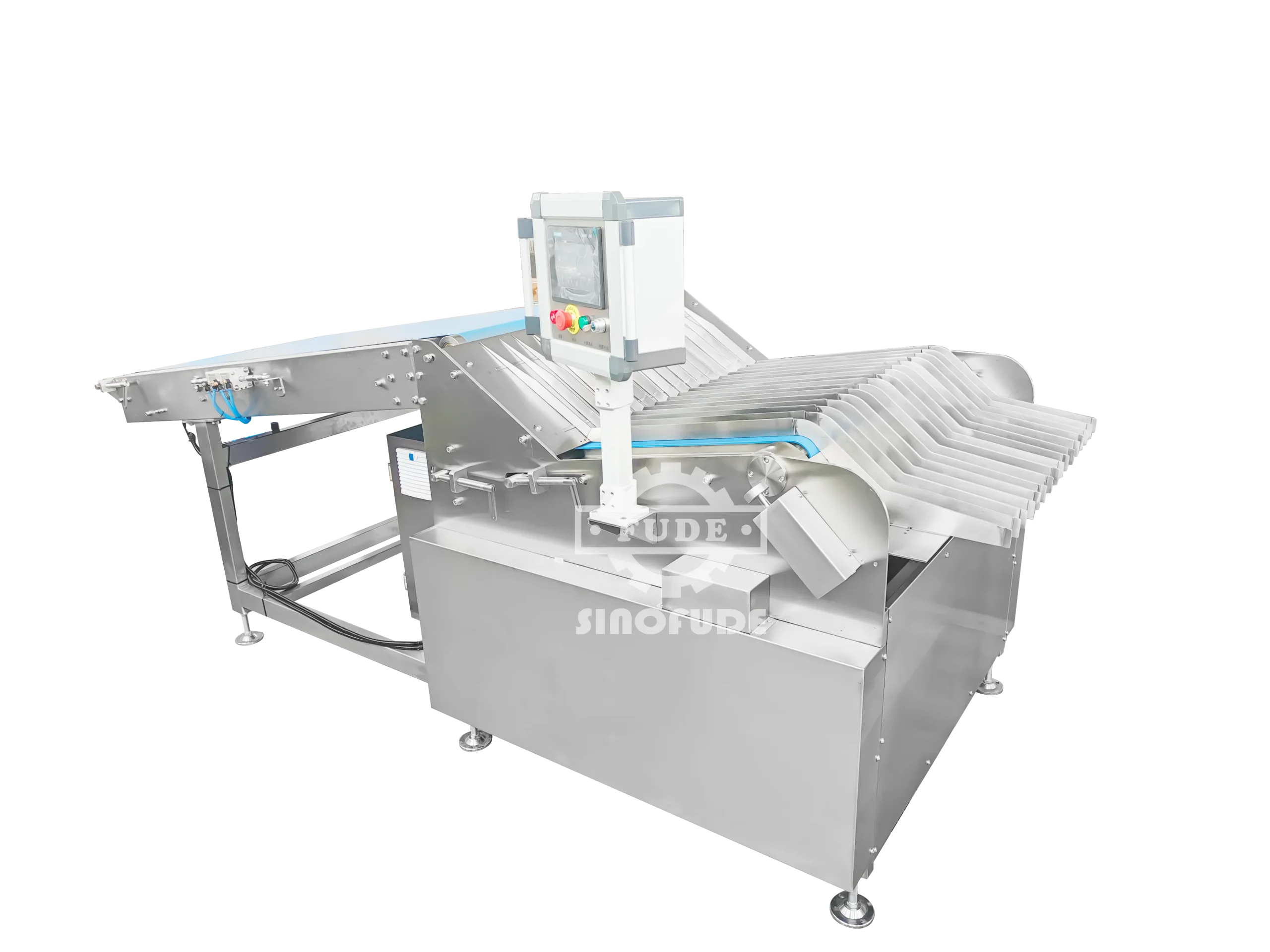

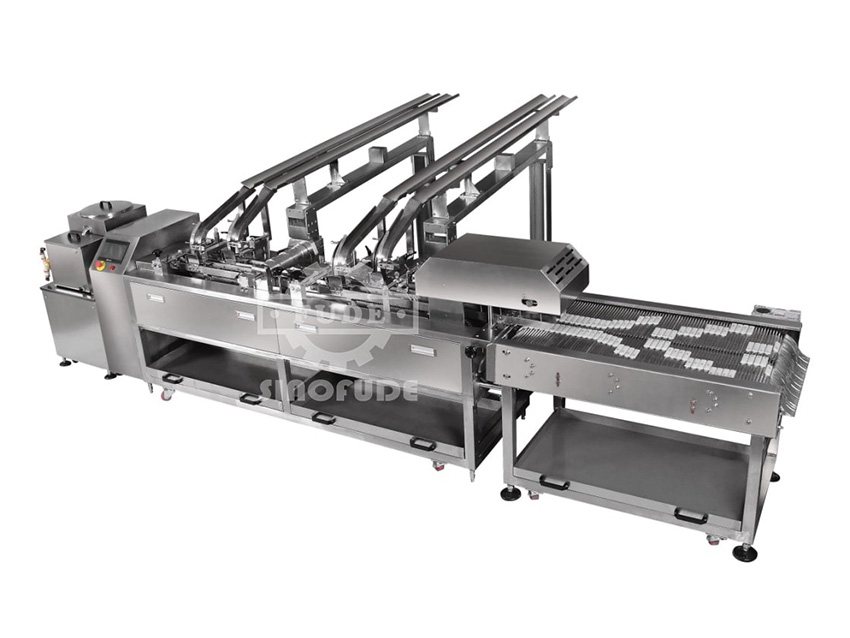

Pre Packaging system