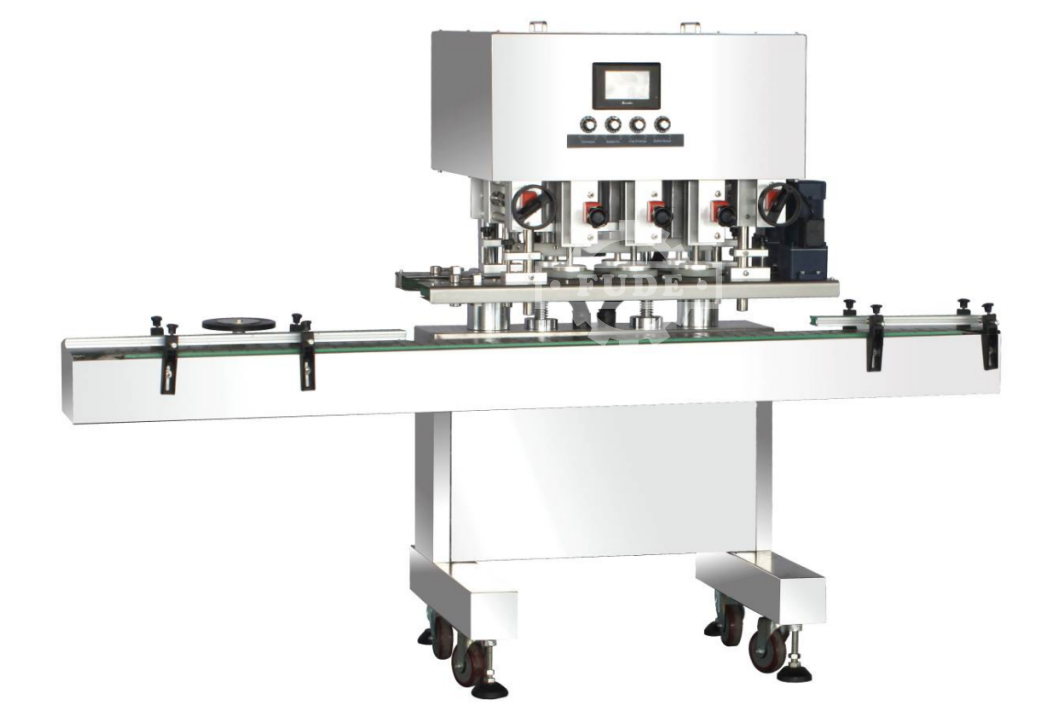

Capping Machine

Home » Packing Machine Production Line » Candy Counting Bottle Packing Production Line » Capping Machine

capping machine is a set of machine, electricity, gas in one of the automation equipment, using PLC control, man-machine interface operation, widely used in medicine, food, daily chemical and other industries. The bottle is sent to the capping mechanism by the belt clamping, and the cap is tightened by three sets of capping wheels. The clamping belt and capping wheel are made of special materials, which not only ensures the durability of the equipment, but also ensures that the bottle and the cap will not cause damage. The device can select the high distortion cap detection after the bottle cap is tightened, and the bottle with unqualified cap is removed to ensure the qualified rate of the product.

Specifications

| Cap Screwing Machine | Parameter |

|---|---|

| Productive capacity | 30-80 BPM |

| Applicable cap diameter | Φ30-Φ80mm |

| Suitable for bottle diameter | Φ30-Φ120mm |

| Applicable bottle height | 50-200mm |

| voltage | 1P 220V 50/60HZ |

| power | 1.3KW |

| Atmospheric pressure | 0.4-0.6MPA |

| Air consumption | 0.5m³/M |

| weight | 550kg |

| Main engine size | 2100×850×1600mm |

| Raise the size of the capping machine | 1000×850×1800mm |

Features

The machine adopts PLC control, Chinese and English interface touch screen, operation display which is clear and easy to understand.

The mode of “one rolling wheel corresponds to one motor” ensures that the equipment is stable and reliable. The torque is consistent, and the adjustment is convenient even under long-term fatigue working condition.

Bottle clip belt can be individually adjusted to fit the bottle cap of different height and shape.

The lifting motor can realize the automatic lifting of the rolling cover host.

Non-toxic synchronous belts and capping wheels are used for parts in contact with bottles and caps.