CBZ500

Home » Popping Boba & Konjac Ball Production Line » CBZ500

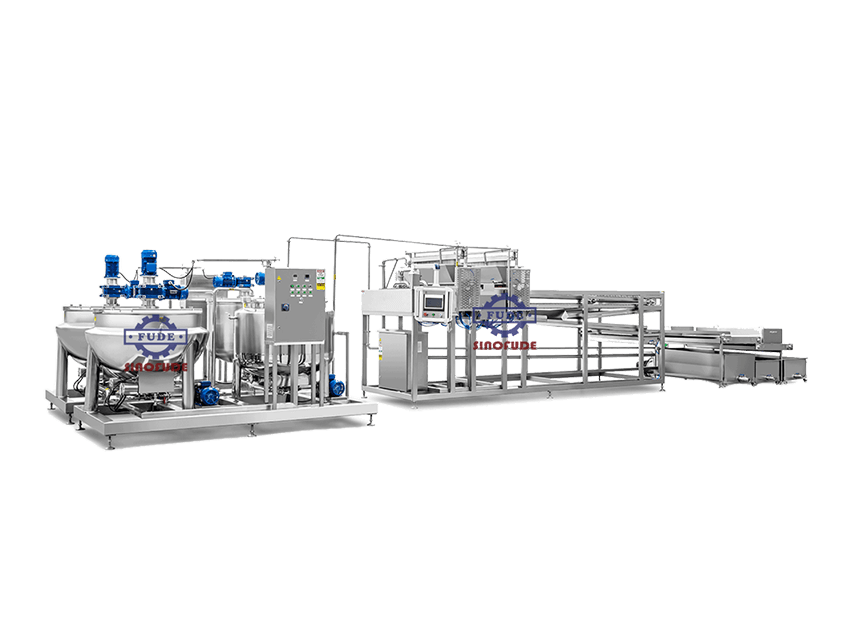

CBZ500 was exclusively developed and produced by Shanghai Fude Machinery and was put into production in March 2010. Adopt PLC control system, fully automatic design. The entire production line is made of stainless steel, which conforms to food hygiene standards. Combined with the production process, the popping boba produced by this production line is bright in color, round in shape, beautiful in appearance and delicious in taste.

In 2022, Sinofude officially launches the S series. By upgrading the depositor to a servo drive and increasing the capacity of the cooking system,

the production line capacity can reach a maximum of 1000-1200kg/h.

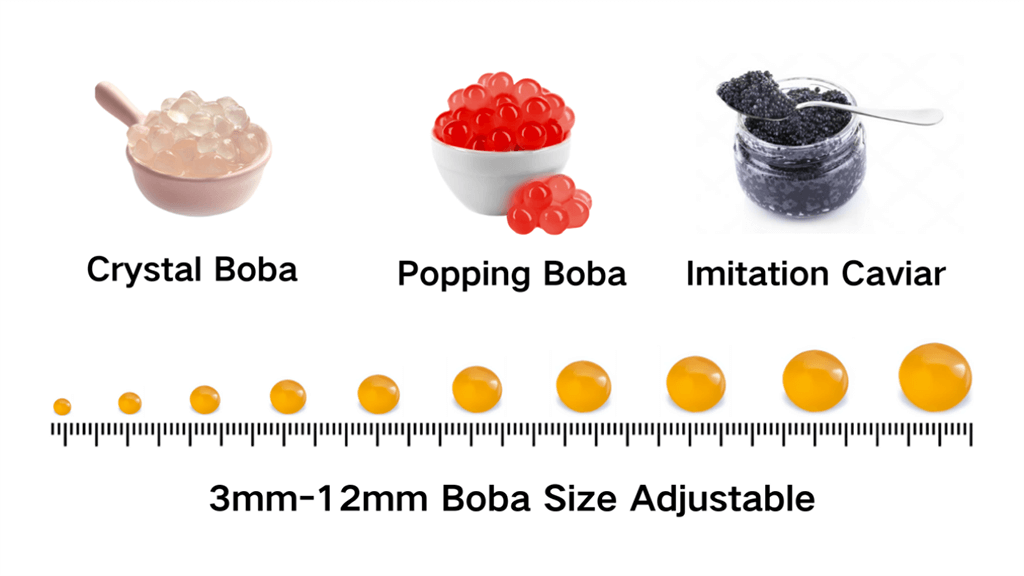

The three types of products the machine can produce:

Specifications

| Model | Capacity | Electric power needed | Number of depositors | Number of Nozzles | Number of depositing plate | Dimension | Boba Size |

|---|---|---|---|---|---|---|---|

| CBZ500 | Up to 500-600kg/h | 138kw (Electric heating) 28kw (Steam heating) |

2 | 198×2 | / | 12.1m*3.5m*2.5m | 5-12mm |

| CBZ500S | Up to 1000-1200kg/h | 141kw (Electric heating) 31kw (Steam heating) |

2 | / | 4×2 | 12.1m*3.5m*2.5m | 3-12mm |

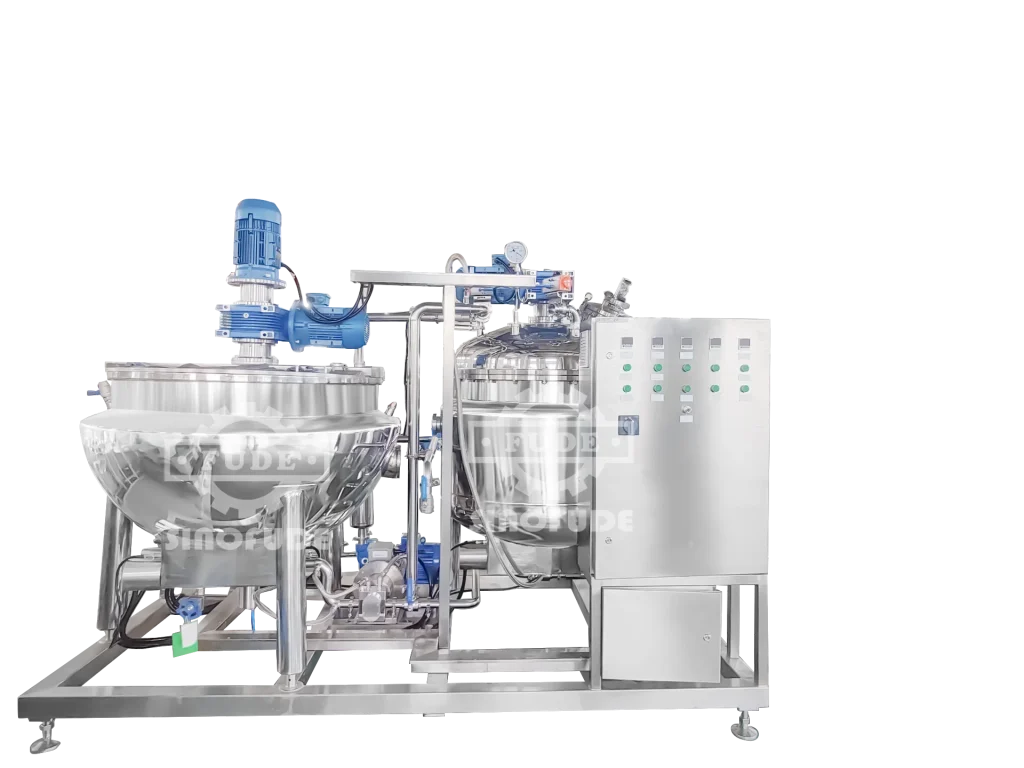

Cooking system

The raw material processing part of the CBZ500 production line. Sodium alginate solution, syrup, etc. are cooked here. It consists of 2 cookers, 2 storage tanks and transfer pumps. It equipped with a high-speed shearing machine and 3-layers insulation jacket. If upgraded to CBZ500S, plate heat exchangers and coolers need to be added to improve ingredients processing efficiency

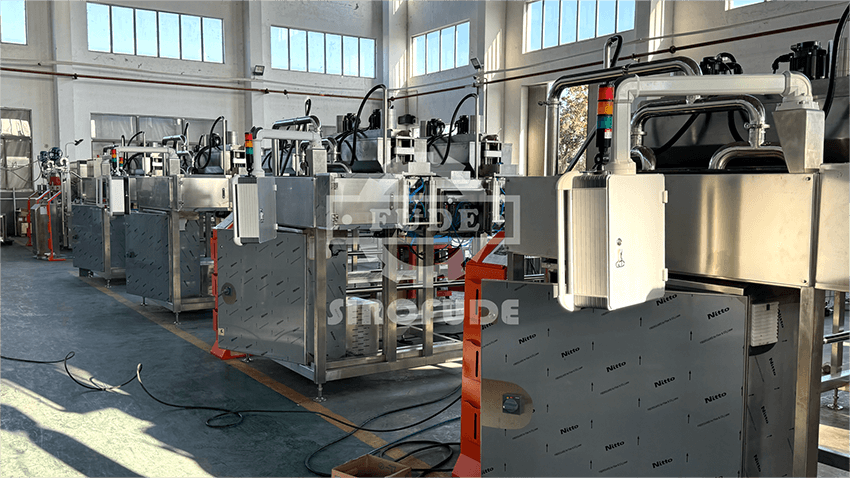

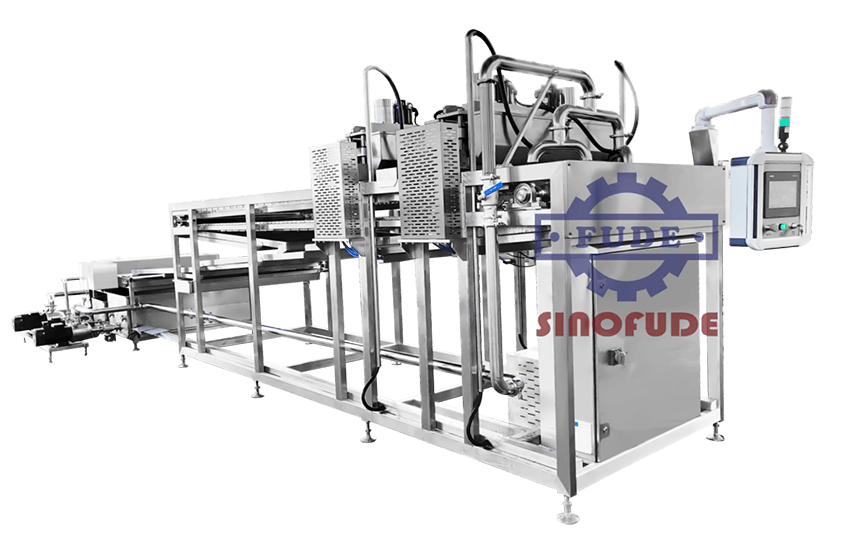

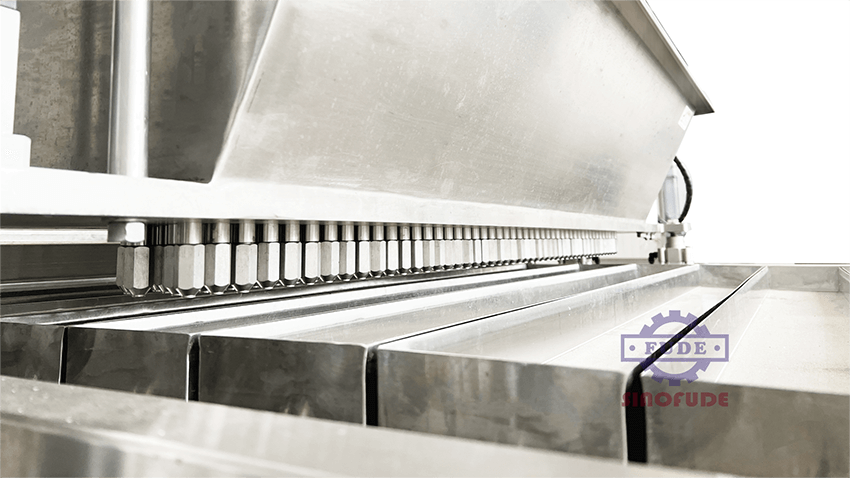

Depositing system

CBZ500 adds a depositor on the basis of CBZ200, doubling the capacity to 500kg/h. CBZ500S is based on CBZ500 and upgrades 2 depositors to servo control, doubling the capacity to 1000kg/h.

2 Depositors

- 2 Depositors, double the capacity

- Can be upgraded to servo control

- No solder joints, no sanitary dead corners, easy to clean, and complies with food hygiene standards

- Capacity and speed can be controlled at will.

- Optional Crystal boba configuration. Add hopper insulation, pipe insulation and wire cutting devices

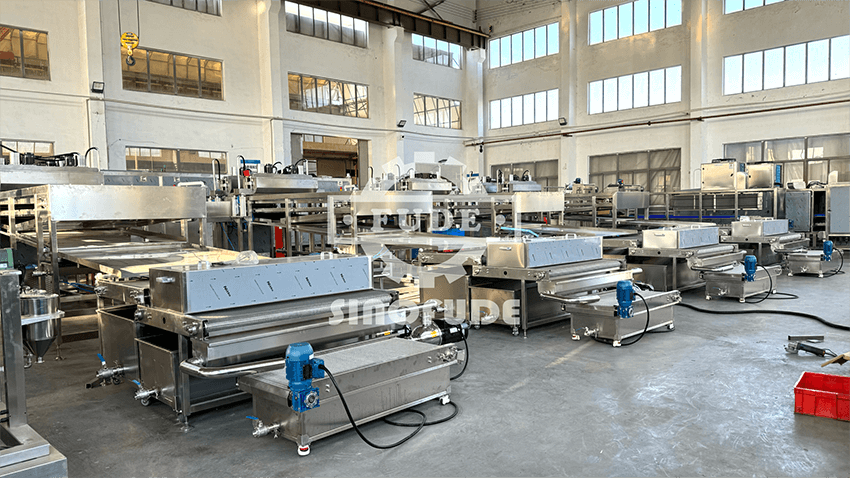

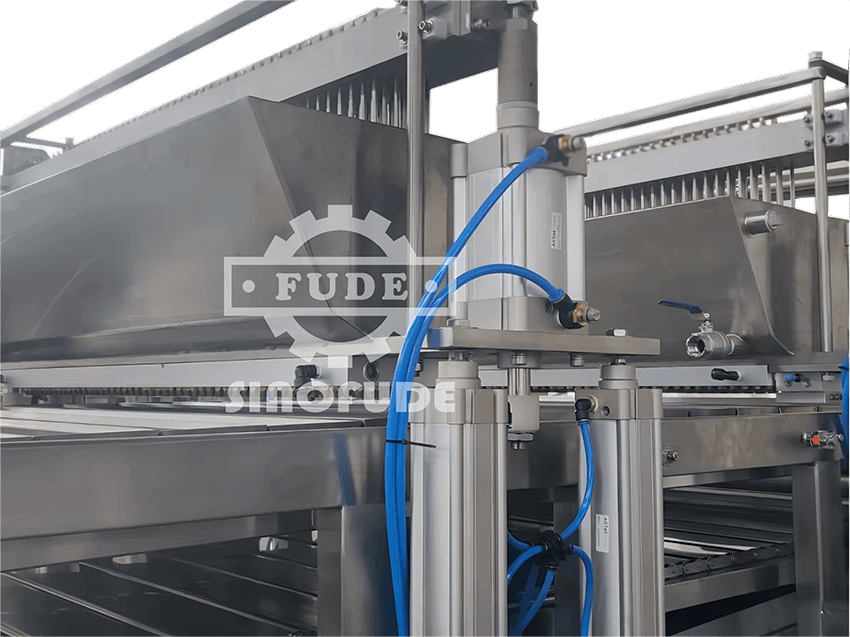

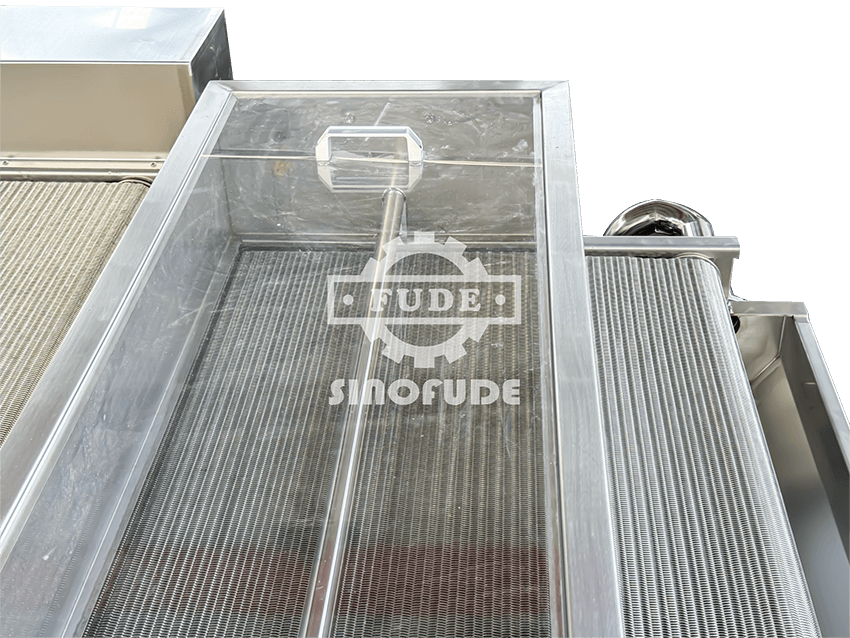

Cleaning system

- Automatic cleaning saves labor costs and ensures product quality and food safety

- Water circulation system, saving costs

- Visual protective cover for easy observation

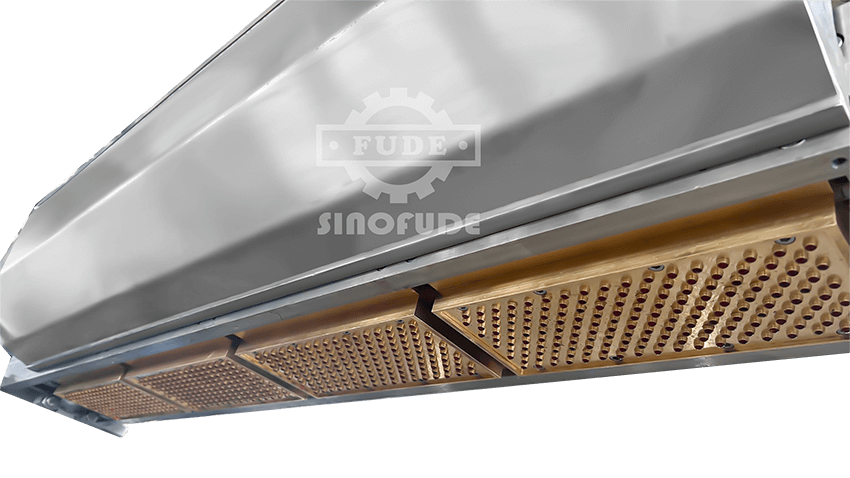

Old model

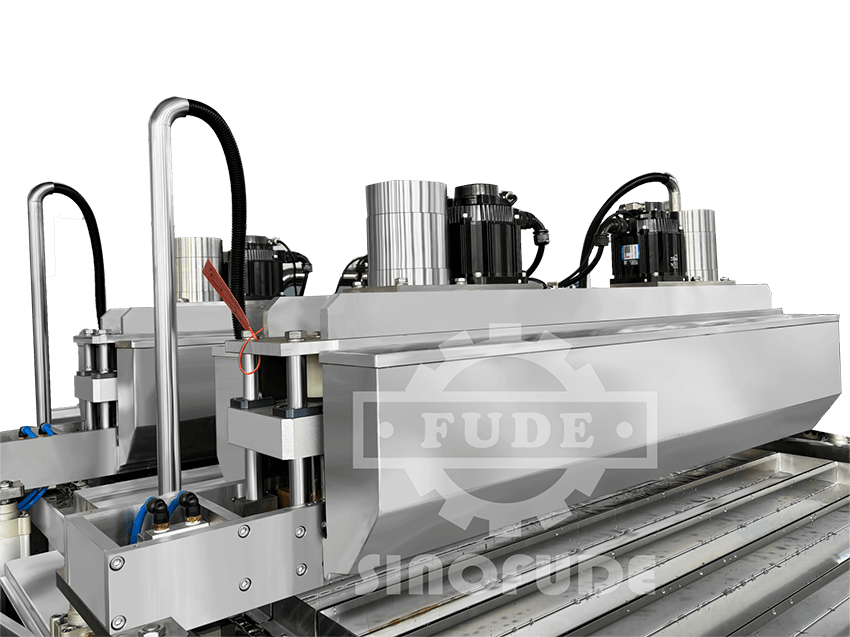

S series

The depositing system controlled by servo motor consists of distribution plates instead of traditional nozzles. Regardless of conventional nozzle size, only a maximum of 198 bobas can be achieved per depositor. But the new distribution plate can adjust the number of deposition holes according to the size of the boba. 8-10mm size boba can reach 816 per depositing. And the new distribution plate is easier to replace, clean and install than the old nozzle, saving labor and time costs