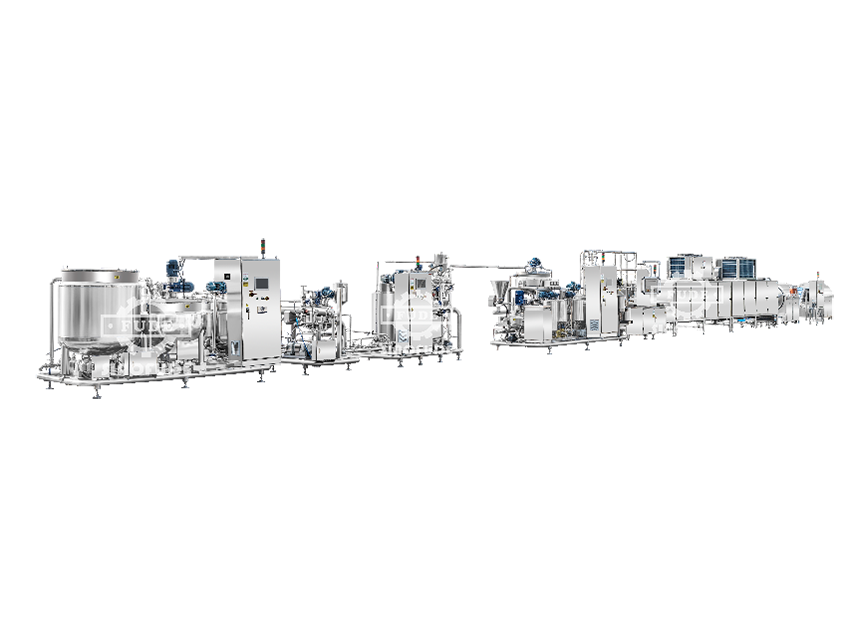

CLM150 Automatic Gummy Production Line

CLM150 auto gummy production equipment able to operate on full production works. It can support up to 150kgs/h.

CLM150 auto gummy production equipment key features include PLC control system, special designed de-moulding device, LED touch panel, and dosing pump. Plus, there is an in-line injection, pre-mixing, and dosing for proportional addition of liquid. Through change-over of moulds, it can formed different shapes.

This production equipment can produce 1 – 2 colours jelly candies. The gross weight of G150 auto gummy production equipment is approx. 8000Kg. Rated depositing times: 35-45n/min. 70kw/220V is the electric power needed.

CLM150 automatic gummy production equipment consists of eleven section including sugar dissolving, conveying, ingredient mixing, essence pigment tank…, drying. The length of the whole line is 16meters.

The three types types of products the machine can produce:

Specifications

| Model | Production capacity | Depositing speed | Power supply | Compressed air consumption Compressed air pressure |

Room temperature (for the cooling system) | Humidity needed for coolling system | Length of the whole line | Refrigerator |

|---|---|---|---|---|---|---|---|---|

| CLM150 | 60,000 gummies per hr | 35-45n/min | 70kw/220V | 0.3 0m3 /min 0.4-0.6 Mpa |

20-25℃ | 55% | 16 m | MT120 15,000 kcal/h |

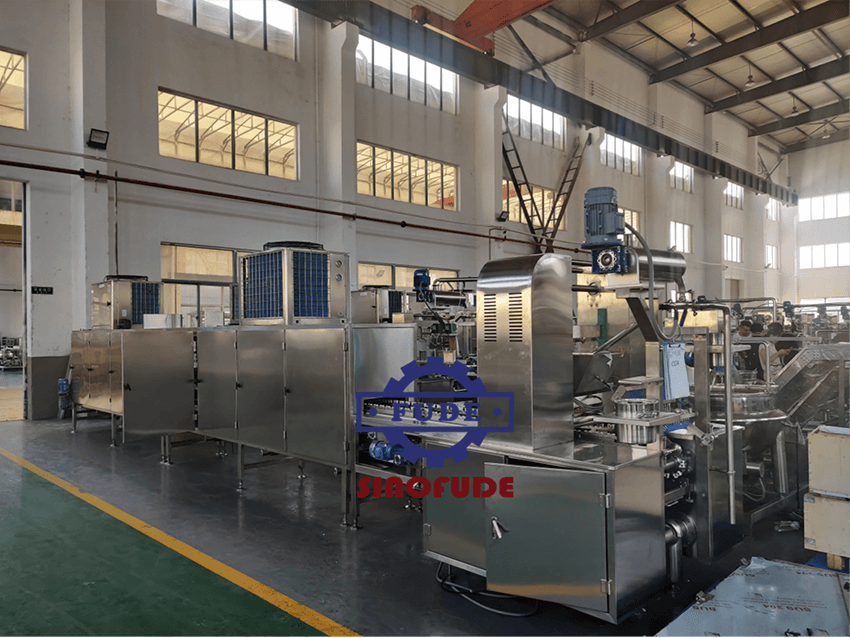

Cooking system

Depositing & Cooling Unit

CFA System

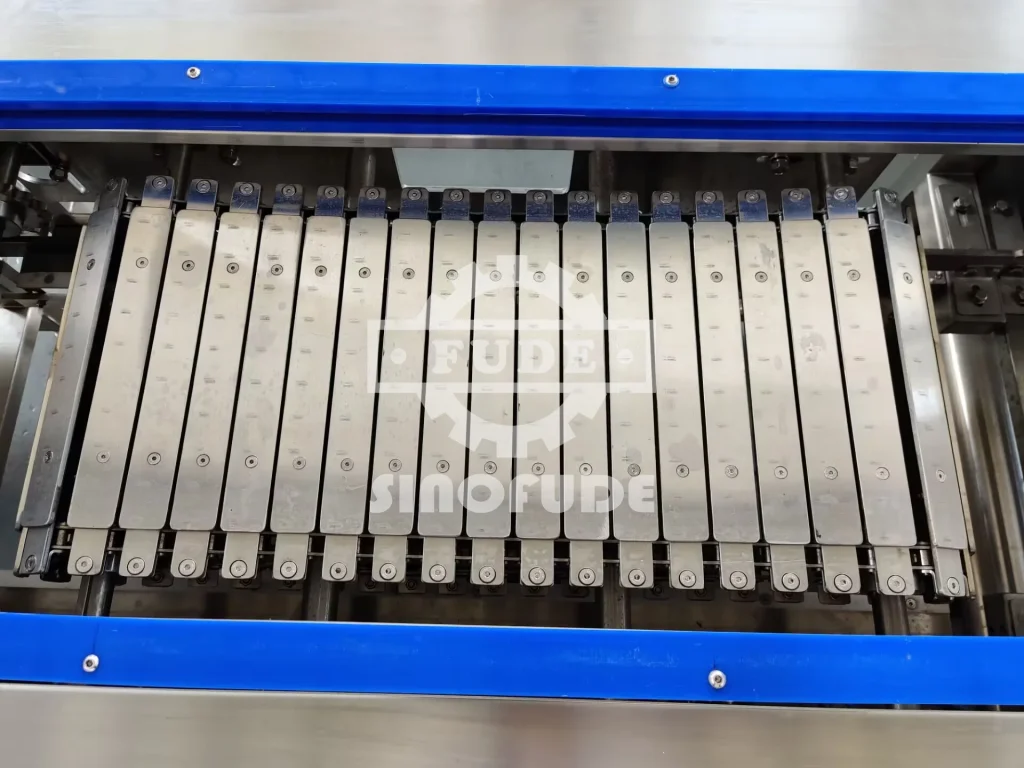

Mold Design

100% de-molding