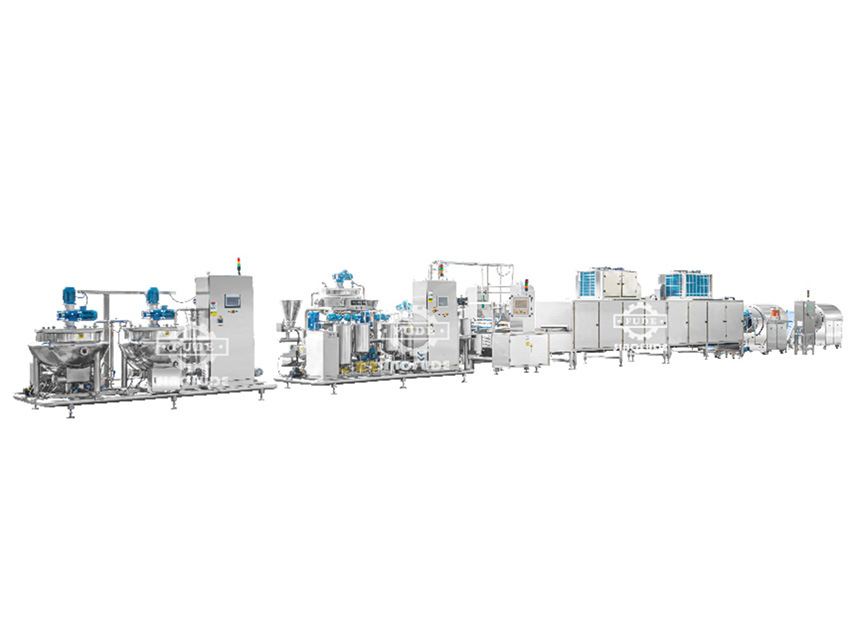

CLM300 Automatic Gummy Production Line

Sinofude developed and manufacture G-300 automatic gummy production equipment that features latest PLC control system. This machine also has in-line injection, pre-mixing and dosing for proportional of liquid.

Sinofude CLM300 automatic gummy production equipment has the capacity of manufacturing different shapes of jelly candies using change-over of moulds. We also attached LED touch panel on each equipment for enhance visual and easy for any operation.

Our CLM300 automatic gummy production equipment has the production capacity of 300kgs per hour. This equipment is available in one color but the jelly candies are two.

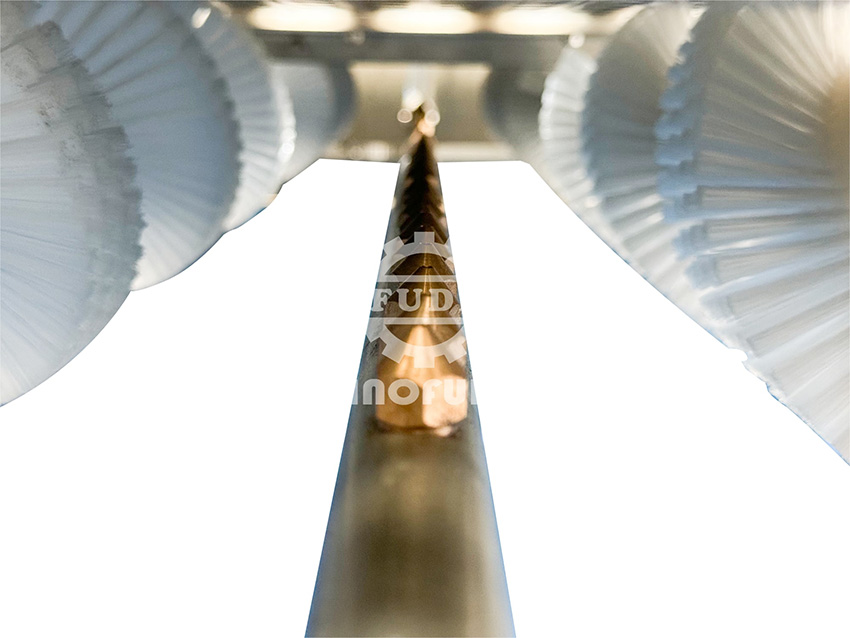

We make sure that our equipment is a special designed de-moulding device. It has special dosing pump for automatic injection of flavours, colors and acids. It is constructed with proper and safe sanitation.

In Sinofude CLM300 automatic gummy production equipment, hard candies can be produced on the same line using the changing moulds. This equipment needs 120kw-380V of electric power in a room temperature of 20-25 Celsius.

We can assure you that our CLM300 automatic gummy production equipment is the perfect machine for your business.

The three types types of products the machine can produce:

Specifications

| Model | Capacity | Depositing speed | Power supply | Length of the whole line | Compressed air consumption | CConditions needed for the cooling system: 1. Room temperature 2.Humidity |

Refrigerator |

|---|---|---|---|---|---|---|---|

| 120,000 gummies per hr | 35-45n/min | 120kw/380V | 16 m | 0.20m3 /min | 0.4-0.6 Mpa | 20-25℃ 55% |

MT120 15,000 kcal/h |

Cooking system

Depositing & Cooling Unit

Molds can be metal with a non-stick coating or silicone rubber with either mechanical or air ejection. They are arranged in sections that can be easily removed for changing products, cleaning coating.

Mold shape: Gummy bear, Bullet and cube shaped

Gummy weight: Ranging from 1g to 15g

Mold material: Teflon coated mould

CFA System

Mold Design