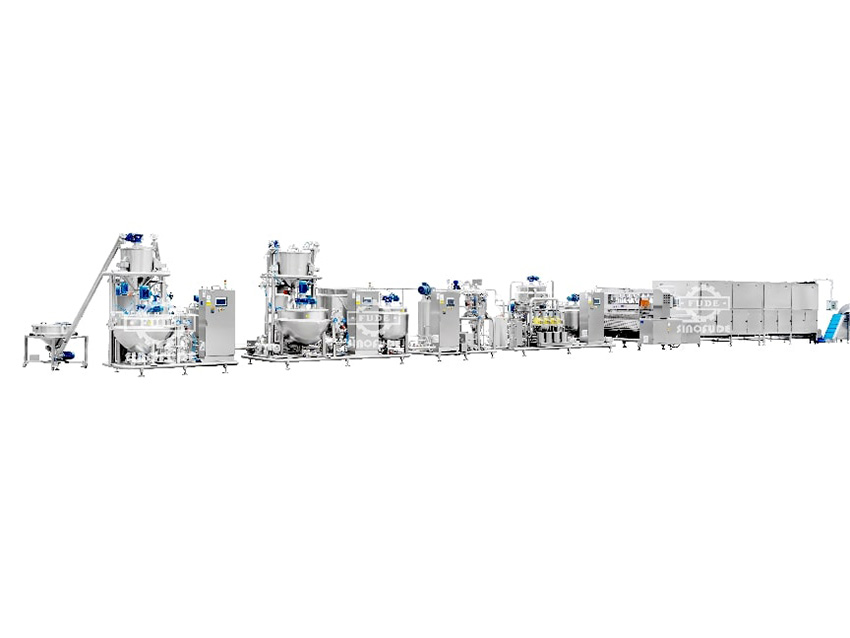

CLM600 Automatic Gummy Production Line

Home » Gummy Candy Production Line » Automatic Gummy Candy Machine » CLM600 Automatic Gummy Production Line

Sinofude’s CLM600 gummy production line is perfect for large-scale gummy production. These machines are capable of producing up to 240,000 gummy units per hour.

Our gummy production lines will execute your idea efficiently and accurately, giving you room for flexible customization.

The hoppers with servo-drive add flavor and color to your product with a variable feed speed peristaltic pump. We have designed 2 systems so that you can make dual-color gummies for your business.

Our CLM600 production lines also feature efficient de-molding devices, PLC controls, LED touch panels, and more.

Sinofude’s machinery is a great option for a starchless CBD/THC/vitamin gummy business.

The three types types of products the machine can produce:

Specifications

| Model | Production capacity | Rated depositing times | Electric power needed | Refrigerator | Conditions needed for the cooling system: 1. Room temperature 2. Humidity |

Length of the whole line | Gross Weight | |

|---|---|---|---|---|---|---|---|---|

| CLM600 | 600kg/h | 25~65n/min | 160kw 220/380V | MT120 15,000 kcal/h | 0.30m3/min 0.4-0.6 Mpa |

20-25℃ 55% |

16-18m | Approx. 8000Kg |

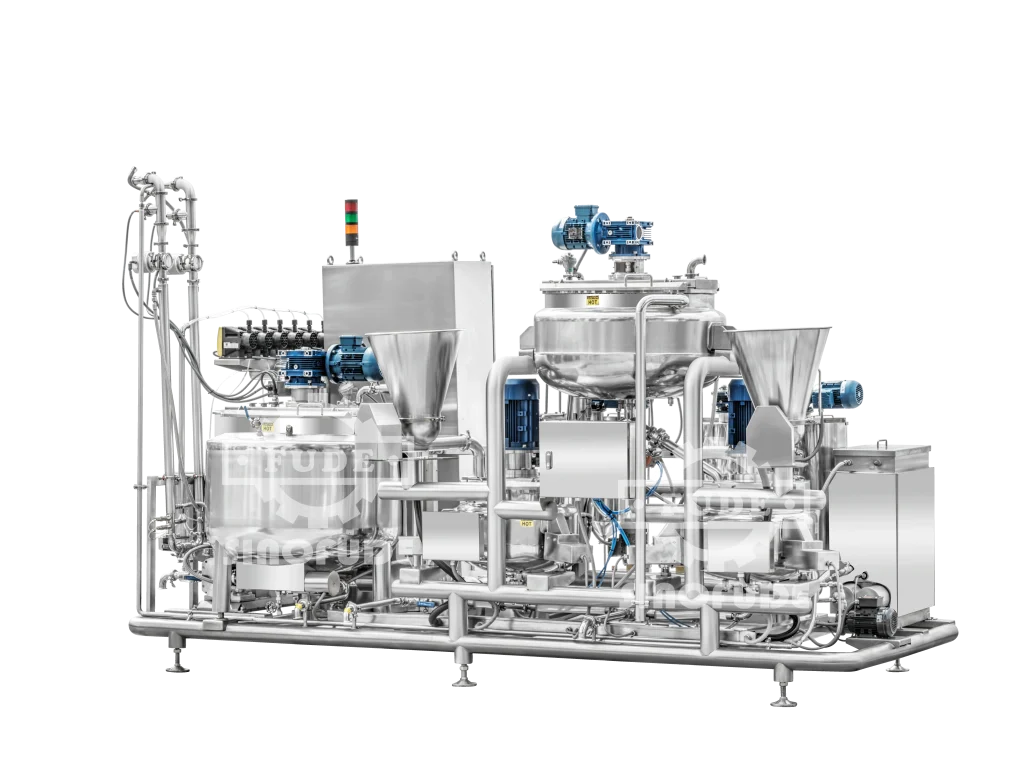

Pectin Gel Mixing System

The raw material processing part of the CJQ series production line., etc. are cooked here. It consists of 2 cookers, 2 storage tanks and transfer pumps. It equipped with a high-speed shearing machine and 3-layers insulation jacket. If upgraded to CBZ500S, plate heat exchangers and coolers need to be added to improve ingredients processing efficiency

Syrup and Gel Weighing and Mixing System

CBZ500 adds a depositor on the basis of CBZ200, doubling the capacity to 500kg/h. CBZ500S is based on CBZ500 and upgrades 2 depositors to servo control, doubling the capacity to 1000kg/h.

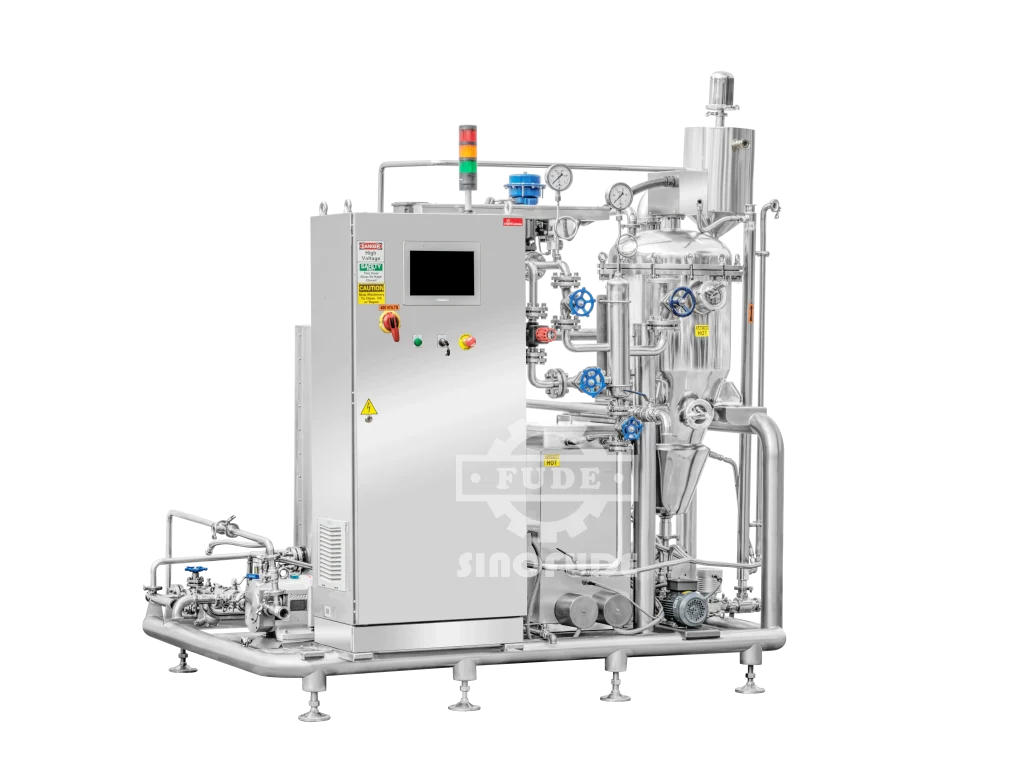

Advanced raising film continuous cooker

PTFE hanging side mixing to ensure food safety. Round tube design, no welds, no sanitary dead corners. Center high-speed shearing, 100% cutting of macromolecular substances.

CFA System

Hot water jacketed hopper to prevent Crystal syrup from solidifying The delivery pump is connected to the extrusion nozzle, suitable for liquids of different concentrations.

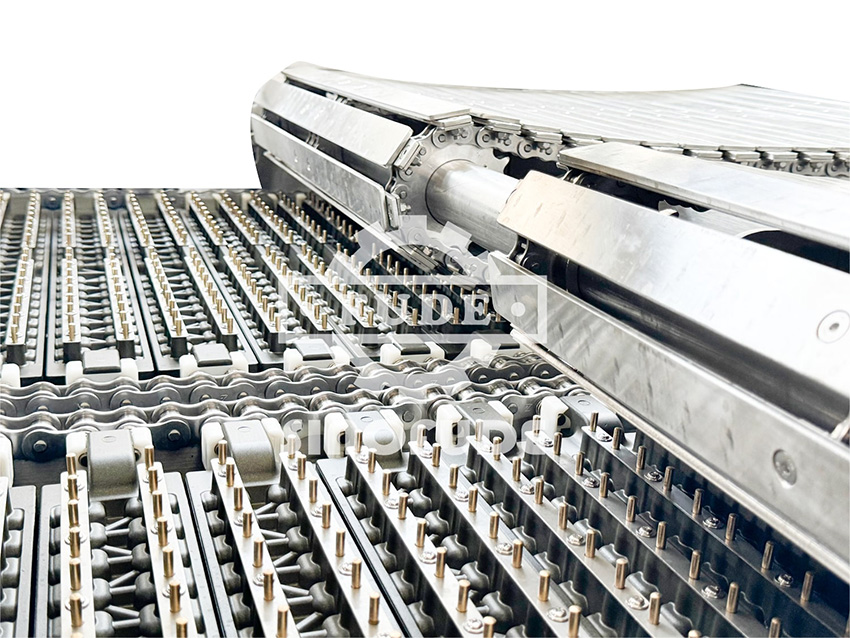

Depositing and Cooling Unit

The scraper is made of mold steel with high hardness and will not stick to the crystal ball syrup. The scraper precisely fits the extrusion nozzle and cuts without residue. The speed is adjustable

Hot water jacketed hopper to prevent Crystal syrup from solidifying The delivery pump is connected to the extrusion nozzle, suitable for liquids of different concentrations.

Servo depositor

The scraper is made of mold steel with high hardness and will not stick to the crystal ball syrup. The scraper precisely fits the extrusion nozzle and cuts without residue. The speed is adjustable

Mold Design

Hot water jacketed hopper to prevent Crystal syrup from solidifying The delivery pump is connected to the extrusion nozzle, suitable for liquids of different concentrations.

Servo depositor

The scraper is made of mold steel with high hardness and will not stick to the crystal ball syrup. The scraper precisely fits the extrusion nozzle and cuts without residue. The speed is adjustable