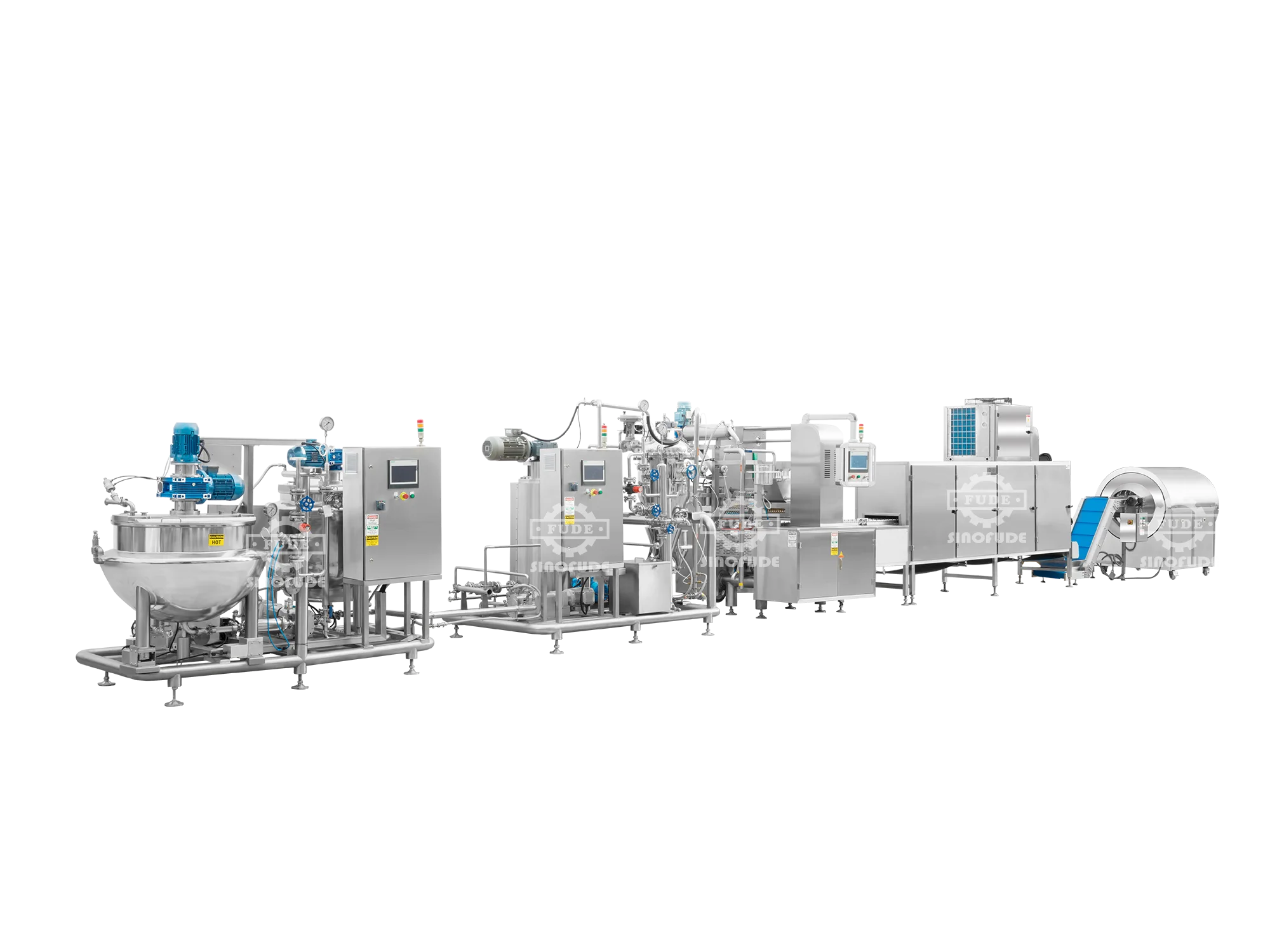

CLM80 Automatic Gummy Production Line

Home » Gummy Candy Production Line » Automatic Gummy Candy Machine » CLM80 Automatic Gummy Production Line

Sinofude CLM80 Automatic Gummy Production Equipment is a stand-alone system capable of full production duties.With speeds up to 30000 gummies per hour, it is perfect for small to medium production runs. This equipment can produce gummies in one or two colors.

The production capacity of CLM80 Automatic Gummy Production Equipment is Up to 80kgs/h. It has PLC control system and LED touch panel for easy operating.

This Automatic Gummy Production Equipment matches special designed de-moulding device, by change different moulds to help you make many kinds of shapes gummies. It has dosing pump for automatic injection of colors, flavours and acids to make your operate fully automatically.

The three types types of products the machine can produce:

Specifications

| Model | Production capacity | Electric Power Needed | Chiller (optional) | Compressed Air Consumption | Compressed Air Pressure | Room Conditions: 1.Room Temperature (°C) 2.Humidity (%) |

Approx. Length of the Line w/ Automatic Coater: | Weight |

|---|---|---|---|---|---|---|---|---|

| CLM80 | 20,000-30,000 gummies/hr for 3g gummy (Up to 50-80kg/h) | 220V/3hp/60Hz(or as required) | MT120 15,000 kcal/h,5hp | 0.5m3 / min | 0.4-0.6 Mpa | 22~25 50 or Bellow |

59.10 ft | Approx. 5000Kg |

Cooking system

The jacket cooker and storage tank are designed on a rack for easy operation and cleaning. The electric control cabinet controls the processes of stirring, boiling, mixing, storage, etc. The jacket cooker is used to dissolve raw materials, the formula ratio of glucose syrup, sugar, water, gel powder, etc. is put into the cooker, melted, and boiled, after boiling to a certain temperature, transferred to the storage tank through the pump to ensure continuous production. The plates and racks are made entirely of stainless steel. The cooker can be electric or steam heating; the tank is heated by a warm water layer, with stirring, connected with the hot water tank, used to slightly reduce and maintain the material temperature so that the liquid temperature is uniform, and the syrup after cooking is transported to depositing machine through the pump.

Depositing & Cooling Unit

The depositing machine is developed with advanced production technology. After continuous improvement and research and development in recent years, the performance has been greatly improved, the degree of automation is higher, and the service life is longer. It is used for the continuous production of various shapes of candies. It is an ideal equipment for the production of high-grade candies, which can produce single-color candy, double-color candy, and center-filled candy.

CFA System

Combine Static and Dynamic Mixer with piston type dosing pump for much better mixing with color and flavor and other ingredients.

Mold Design

Quick release design mould carrying chain with quick release type mould makes the mould changeover just within 1hour.

100% de-molding.

Chain type de-molding with two brushes installed and with air knife for 100% de-molding.