Counting Bag Packing Machine

SINOFUDE candy counting bag packing machine adopts advanced European and American technology, using high-speed photoelectric detection of falling objects, and supplemented by highly optimized algorithms for calculation and statistics. Then through the synchronous control module to achieve accurate counting and packaging.

The equipment is compact in appearance, beautiful in shape and convenient in maintenance. It is widely used in the counting and packaging of particle objects in pharmaceutical, health care products, food and other industries. Such as: tablets, sugar coated tablets, soft or hard capsules, seeds, nuts, frozen balls and so on.

Specifications

| Electronic counting machine | Parameter | Remark |

|---|---|---|

| Number of vibrating table channels | 8 | |

| Productive capacity | 20-30pcs/min | related to the specification of packing material and granule |

| Counting range | 5-100pcs | |

| Material specification | T3-10mm;D3-24mm;L3-26mm | |

| Container specification | L50-200mm;W40-150mm | Different bag widths need to change the specifications |

| Air source | 0.5-0.7Mpa | |

| Air consumption | 130L/Min | clean air |

| Power source | 1P 220V 50HZ | |

| Power | 2.5KW | |

| Weight | 400KG |

Features

A wide range of application: the same equipment can be suitable for different shapes, sizes of products packaging; Easy to switch between different specifications; easy to adjust;

- Precision of the number of pieces: using an independent optical inspection system, so as to ensure a high level of precision and speed of the number of particles;

- Multistage vibration feeding: each stage can be adjusted separately.

- The surface is made of stainless steel and non-toxic, chemically stable food grade non-metallic materials, easy to clean, no dead corners;

- It is equipped with missing bottle and blocked bottle detection photoelectric, and can effectively control the normal operation of the whole system, no bottle, blocked bottle automatic stop, to be restored after automatic operation;

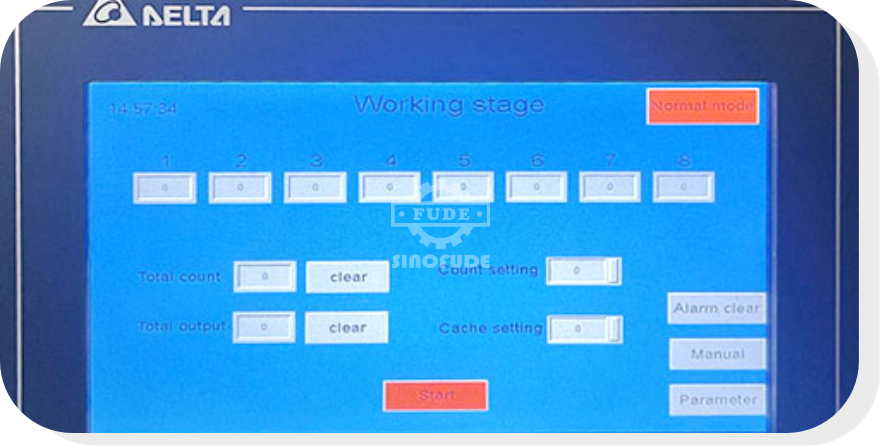

- Simple operation, intelligent design, various operating parameters can be directly set in the man-machine interface according to needs;

- Mechanical adjustment part of the structural combination and embedded buckle design, so that different products conversion adjustment and cleaning is simple and time-saving;

- Automatic fault diagnosis, comprehensive real-time monitoring alarm and display;

- With parameter storage function, replacing the product without debugging, it directly can call the original stored parameters;

- Cylinder positioning bottle, fast and accurate, can be single production. And it can also be connected to the production line;

- Complete equipment supporting information (including equipment structure, principle, operation, maintenance, repair, upgrade and other explanatory information) to provide full guarantee for the normal operation of the equipment.