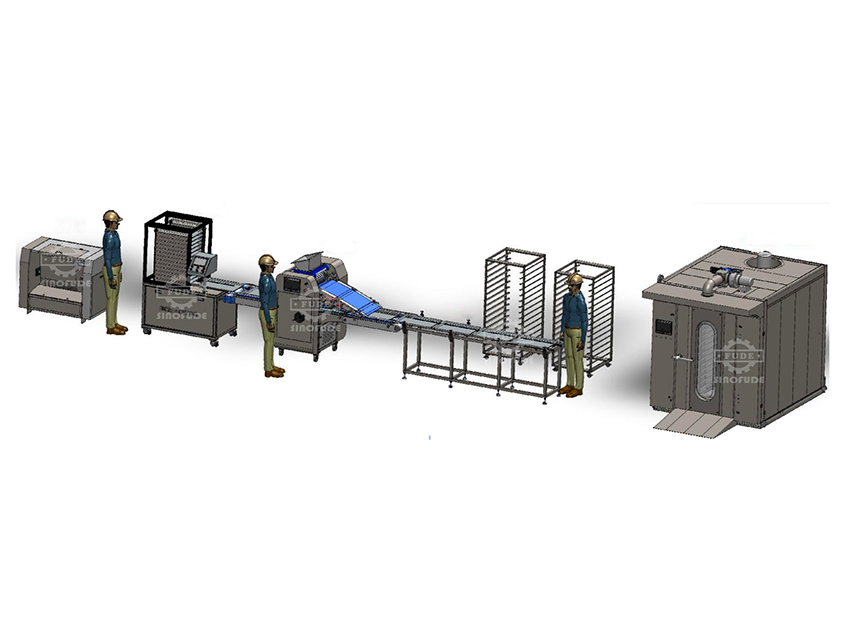

TS Series

In a semi-automatic biscuit production line, operators need to monitor the operation of the production line, perform manual operations and perform quality inspections to ensure that the products meet quality standards.

Automated equipment is mainly used to improve production efficiency, such as automating dough mixing, biscuit cutting and baking stages.

This kind of semi automatic production line, which combines manual operations and automated equipment, can increase production capacity and consistency and is suitable for customers with lower budgets.

Specifications

| Model | Production capacity(kg/h) | Total length(m) | Baking temperature(℃) | Whole line power (kw) |

|---|---|---|---|---|

| TS-400 | 200KG | 15 | 190-240℃ | 60 |

| TS-600 | 300KG | 20 | 190-240℃/td> | 65 |

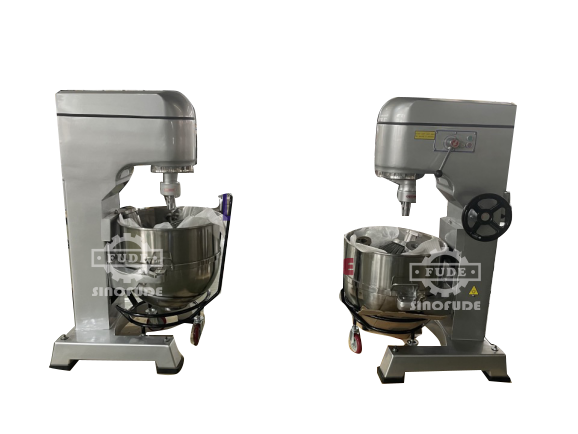

Raw material mixing system

Horizontal mixer (50L) is designated to make dough.

By kneading, pressing and folding, the mixer makes smooth, elastic and ductile dough which is suitable for hard and soft biscuits.

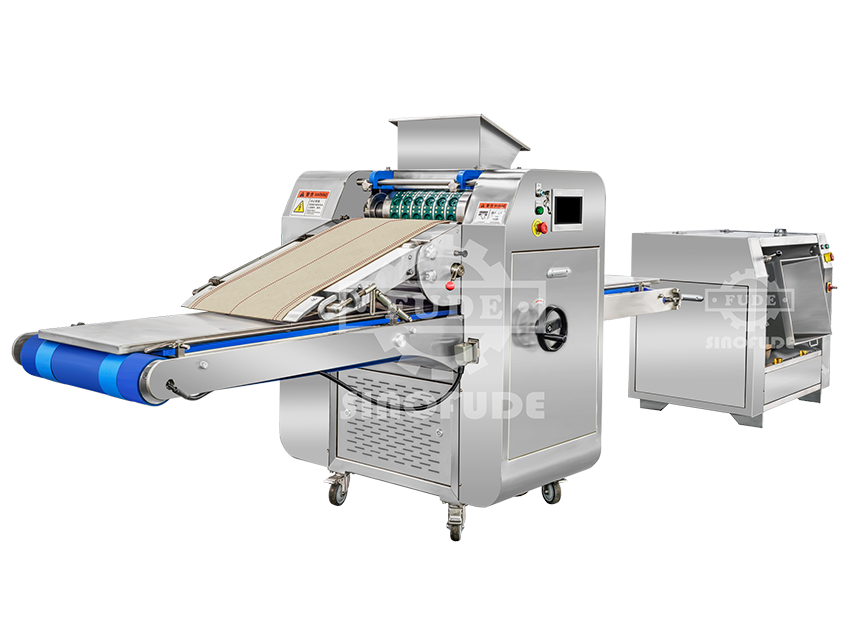

Soft biscuit forming system

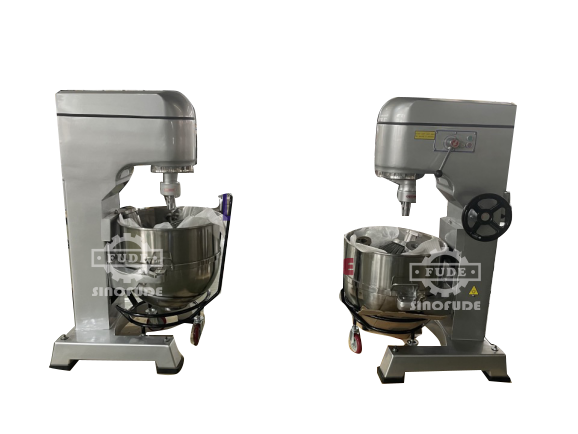

Hard biscuit forming system

The hard biscuit forming system mainly consists of Roller sheeting unit/feeding machine/Dough recycling machine /Double Roller cutter forming machine(for hard biscuit) /Dough separating unit.

After putting the kneaded flour and other raw materials into the machine, the mass is shaped into unripe biscuit and finally all kinds of middle and high grade biscuit at baked boxes through three stage roller molds at one time.